In a constantly evolving world, amidst the global change in dietary habits and digital and technological innovation, the world of pizza enters the future.

This is a world that is constantly evolving and going faster and faster. Amid the global change in eating habits and digital and technological innovation, the pizza world is entering the future. Never like this year technology applied to pizza equipment improved the work of the pizza maker. Thanks to the 5G network and the Wi-Fi connection system, it is possible to connect our machines to cell phones, and with remote control, optimize time, collect data and interpret them; by doing so, it is possible to take actions on malfunctions that until yesterday could only be solved by physically moving, while today they can be dealt with thanks to a smartphone. Just think about the daily need for pizza chefs to turn on pizza ovens, which is generally done at least 1-2 hours in advance, to ensure their correct cooking temperature for service. Using technology, it is possible to control all the functions of the oven in real time directly from a smartphone, turning it on at the right time based on the information received. All this in a totally practical way and saving energy at the same time.

Temperatures, control and regulation of the top and bedplate heating elements of the electric oven, management of flame levels in traditional ovens, rotation speed of the cooktop, programs and consumption data, are all technological innovations that until recently were mainly intended for industrial settings and are now available to everyone; thus, productivity and services are increased, and malfunctions are corrected, resulting in reduced operating costs and consumption.

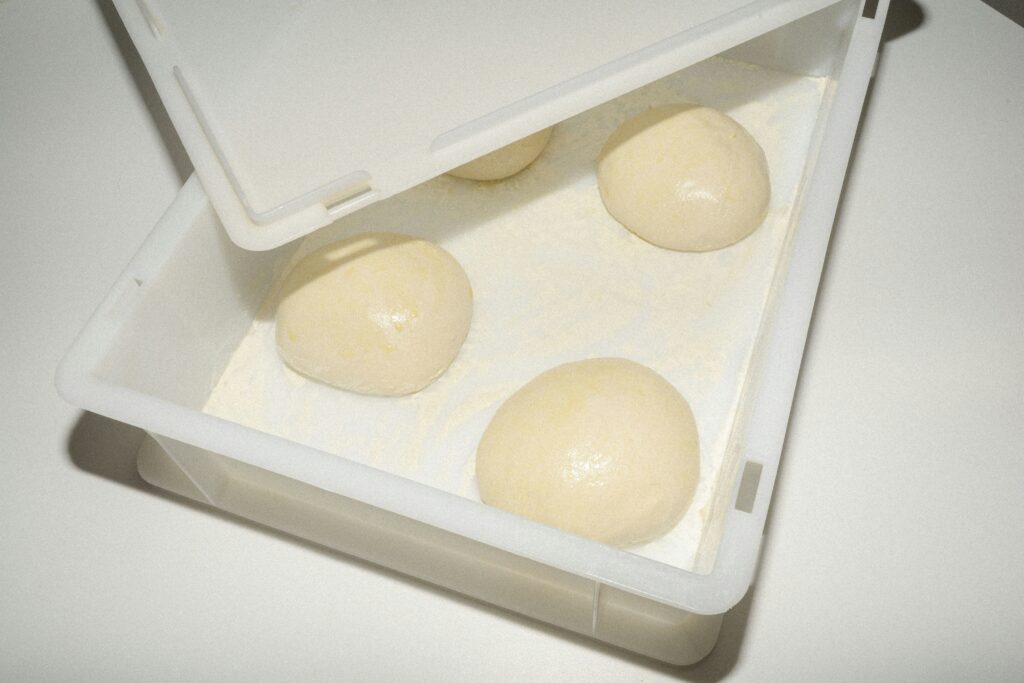

Increasingly advanced technologies are also available for handling spiral and plunging arm kneaders 4.0 and planetary kneaders 4.0. Increasingly smart machines equipped with full-color touch screen displays and Wi-Fi connections for online technical assistance and diagnostics, or recipe sharing for pizzeria baked products, with programmable processes in terms of kneading time, temperature control, and the speed at which the tool is working in the tank.

These needs increasingly embrace market requirements, according to which the pizza maker is involved in recipe sharing, especially in large chains where dough making is standardized by procedures and remote point-of-sale control systems.

The pizzeria of the future is increasingly smart, and this situation often emphasizes the contrasts between the more traditionalist pizza makers and the more technological ones, leading to unnecessary frictions that ignites the debate on the most qualified equipment to make the “perfect pizza.” The adoption of cutting-edge equipment is also stimulated, in some cases, by the benefits that the market offers, such as the possibility of taking advantage of a tax credit equal to 40 percent of the investment. An element that often convinces even the most skeptical ones.

Another topic of major discussion is definitely the pizza vending machine. In a time where everything runs fast, including food, these pizza “machines” have found their way in areas where quickly consumed food is a necessity. Controversial or not, these vending machines work with remote management of all the features visible on the display: pizza picture changing, advertising, pizza ingredients, allergens, cooking time, selling price, cooking and cooling parameters settings, upgrades and maintenance. Technological innovation has led to this new way of proposing pizza that offends some of us pizza makers and the passion we put every day into the making of doughs, which tell their own path and history. Romantic elements such as these clash with the ongoing change in our eating habits, which result instead in favor of systems that have little or no tradition.

Digital innovation embraces not only the world of pizza but all gastronomic fields. My collaborations with Professional Schools of Haute Cuisine consolidate my awareness that even modern chefs have cutting-edge equipment that allows them to work with simplicity, speed and smart control of all cooking processes. Innovative management systems that have improved the working methodology by optimizing even the cleaning steps, which can be scheduled during the activity’s off times. Even with regard to non-technological equipment such as pizza peels, research has developed and brought to the market pizza peels that are increasingly revolutionary in shape and made with lighter and lighter materials (carbon fiber), realized according to different types of preparations. Perforated, with grooves that facilitate the elimination of excess flour and with ergonomic handles that are easy to grip, having the most curious shapes that however guarantee excellent use.

In my vision, food industry technology in the near future will be increasingly smart and innovative, following the changes in our eating habits and lifestyles, and evolving according to the needs emerging from the population, which are based also on consumption. Industrial choices will certainly consider the effectiveness of machines but will be increasingly attentive and aware that it is essential to distribute resources fairly, inform and educate on proper nutrition, address the ever-present issue of waste reduction, and promote sustainable agriculture. Essential approach to respect future generations and the global balance of our planet.