Baking is a key “ingredient” to obtain a quality baked product. It is often underestimated, as well as the management of oven chamber temperatures, resulting in poor-quality, often undigestible products.

When you put the pizza into the baking chamber, regardless of temperature and type of pizza – whether it is a classic pizza, a pan pizza, or a pizza in-pala – the heat spreads in three different ways: from below, through heat conduction transmitted to pizza by the oven bedplate; by irradiation, through the heat coming from the top and walls of the oven; and finally by convection, a method of baking in which heat is transmitted through the evaporation of the water contained in the dough.

During baking, important chemical-physical transformations take place inside our product, involving both the organoleptic aspect and digestibility. Adequate oven temperature is crucial, as these chemical-physical transformations start immediately, as soon as the pizza enters the oven: a rapid increase in yeast activity, high enzyme activity, starch gelatinization, water evaporation and the Maillard reaction.

Once we understand the baking process, we need to carefully evaluate the temperature of the oven chamber, depending on the type of pizza we are going to make. In particular, this is true for pan-made products, where the amount of dough requires that we not set the temperature too high, which would otherwise lead to caramelization on the outside while leaving the inside raw. A temperature that is too low, on the other hand, would create a pizza that is too crispy, due to the prolonged and slow evaporation of water. Even pizza in pala needs a very carefully controlled baking temperature, for it has typical characteristics such as crispness and high-water content.

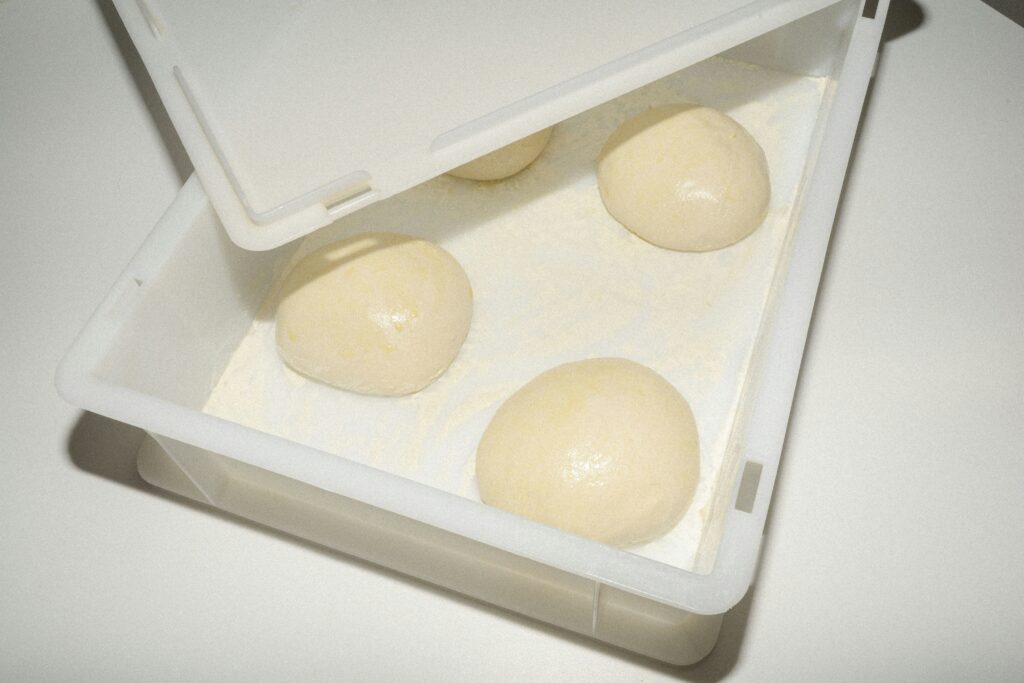

To obtain an excellent final product, certainly pan pizza, pizza in pala, and small-pan pizza are types of pizza that need prebaking; during this process, the Maillard reaction should not occur on the surface and the product should be moist inside. To the touch, the product should still feel soft and not fully baked. An excellent technique is to use steam.

What are the benefits of pre-baking?

The main one is definitely the management and optimization of processing time. After prebaking and cooling the bases on special grids at room temperature, you can go on to final baking or you can store them, bagging them, and bringing them to controlled refrigerator temperature (+ 4 °C) or blast chilling them – all of them or just some of them – storing them in the freezer.

Furthermore, in case of dough requiring long baking or containing large amounts of liquids, pre-baking ensures proper liquid evaporation in the first phase and improved baking of the filling ingredients in the second one and gives beautiful final appearance.

Prebaking can be done with or without tomato, something you can choose in relation to the type of recipe.