It is a very used ingredient in bread making, but it has unique characteristics for different types of processing. Let’s discover its peculiar properties and how to use it.

The browning of many bakery products displayed in the window of the baker’s shop, or the inviting color of a nice pizza offered in a pizzeria are the result of the baker’s conscious choice of a flour with an adequate enzymatic charge and of the adoption of some tricks in the dough, such as the addition of a natural improver like malt.

The term “malt” generally means the product of the milling of a cereal – such as wheat, barley, rice, rye, and many others – which undergoes a germinative process.

Malt is widely used in bakery and in the food industry in order to flavor certain types of food and in the production of alcoholic beverages, such as whiskey and fermented beer.

Among all the cereals used to produce malt, the most suitable for the characteristics of the caryopsis is certainly barley. Before the malting process, barley is selected according to the size of the caryopsis and the percentage of proteins.

After harvesting, barley is cleaned and dried, reaching a humidity of 12%. Subsequently it is immersed in big tanks full of water and it reaches a humidity of about 40-47%; according to the type of malt to be obtained it is left there for a variable time of 38-48 hours.

Once the desired humidity is reached, water is removed for the next phase, germination. During this phase, which varies from cereal to cereal, the grain is put in ideal conditions of humidity and temperature in order to allow the growth of roots, and in about 5 days, green malt is obtained. In this phase the starch contained in the grain is transformed into maltose.

The next process is drying. With a mild thermal treatment lasting about 24 hours, humidity is eliminated by bringing it to 4-5%, and the product obtained is stored in proper silos for the following phases: in order to obtain the different colors, green malt is toasted.

During germination deep transformations take place inside caryopses. Starch undergoes an accentuated hydrolysis by amylases. The high quantity of simple sugars obtained will be useful for leavening and caramelization of the final product and the high presence of enzymes will favor the breakdown of starch contained in flour into dextrins, maltose and glucose.

Not all commercial malts have the same characteristics. To understand the difference between one type of malt and another, we can refer to the enzymatic-diastatic power. In fact, there is diastatic malt and non-diastatic malt, which differ for the presence or absence of diastatic enzymes that transform starch into simple sugars.

Non-diastatic malt will not increase fermentation power (because of the absence of diastatic enzymes), however it will give the finished product a more intense color and a very strong aroma. Diastatic malt has a different role; its presence, in fact, favors active fermentation reducing both resting and processing times and promotes a higher browning of the crust, a more developed alveolation with a consequent lightness and digestibility, as well as more intense taste and aroma.

Pollak unit represents the quantity of reducing sugars expressed in grams as maltose, produced by saccharifying action on starch by distase contained in 1000 grams of the substance in 30 minutes at a temperature of 40°.

Usually, Pollak values for malt vary from 6000-8000 to 24000 Pollak Units. On the market, several types of malt are available and when buying, the choice must be evaluated according to the value of Pollak Units. Malt flour obtained by dry grinding, for example, has a high diastatic power, contains few sugars and its Pollak value is around 13000 Units.

Malt extract in syrup is obtained by wet grinding malt. It has a high diastatic power and many sugars (almost 85%) with a Pollak value of 16000 units. With a further concentration of malt, it is possible to obtain concentrated malt extract in syrup, a product with a very high diastatic power, a very high quantity of sugars and a Pollak value of 24000 units. Finally, on the market it is also possible to find malt extract in powder, obtained by drying malt extract in syrup. It has a very low diastatic power but on the other hand it contains a lot of sugars equal to 89-90%. This latter has a Pollak power of 8000 units.

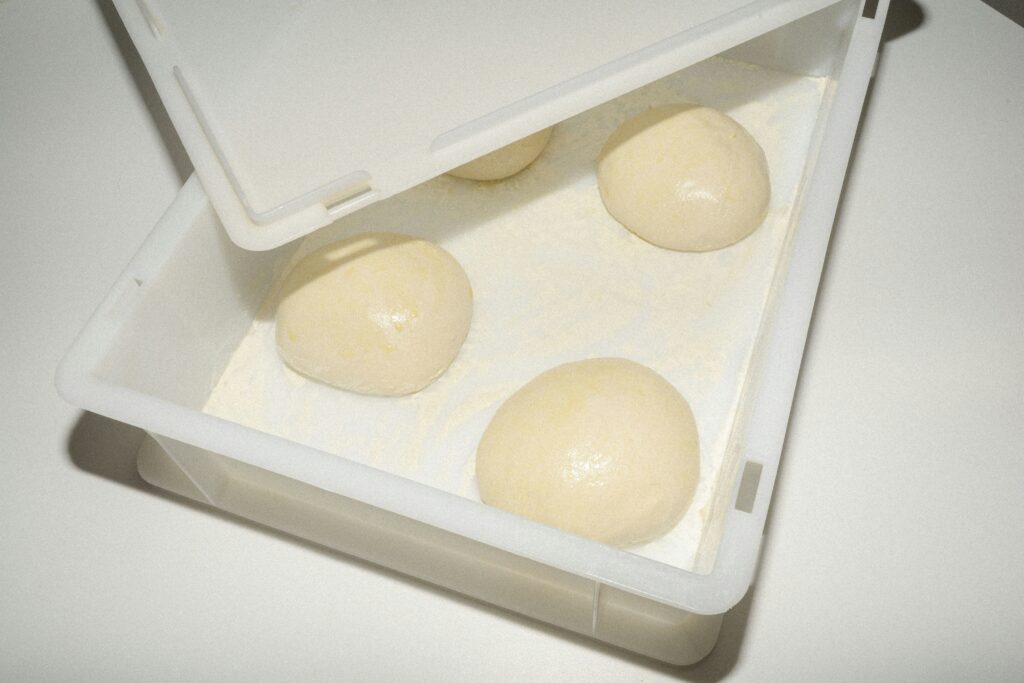

The Pollak index of malt determines not only its value, but also the quantity to be added to the dough. To obtain a quality product, it is necessary to accurately evaluate the type of malt to be used. It is therefore important to understand the type of dough: direct, indirect with biga or poolish, with mother yeast, with long or short leavening; then, it is necessary to have clear what kind of product is desired. In long leavening dough and in indirect dough where the consumption of sugar by yeasts is high, the addition of malt is essential.

It is usually added to flour in quantities ranging from 0.3% to 1-2.5% according to the type of malt. An excess of malt will produce a too moist and sticky crumb. Testing the product with continuous experiments is surely the best approach to obtain better results.

If we use sugar in the dough instead of malt, is it the same?

There are professionals who add simple sugar, sucrose, to the dough, but it is different from adding malt. Simple sugar provides the yeast with a massive and instantaneous amount of nutrition while adding malt provides constant nutrition over time and in addition to the maltose, there are large amounts of enzymes that will break down the starches, giving the yeast food gradually over time.