When preparing pizza, as well as any other dish, you have to deal with all the issues related to the proper food preservation. Let’s discover together the freezing technique

Until some decades ago in pizzerias it was quite difficult for equipment such as refrigerators or even freezers to be used because both the dough and all the toppings were prepared within the same day and were consumed in a short time.

Starting from the end of the 80’s, with the opening of the first pizzeria schools and, above all, through study and experimentation, an evolution started, bringing several innovations in a short time. It has been discovered that, thanks to a sort of “maturing”, that is an adequate rest at a controlled temperature (in the fridge), pizza dough, as well as many other protein foods, is able to transform and therefore develop a better digestibility. This new awareness gradually encouraged all operators in the world of pizza to use the refrigerator not only to improve the dough quality but also to guarantee higher quality and healthiness of all the toppings ingredients.

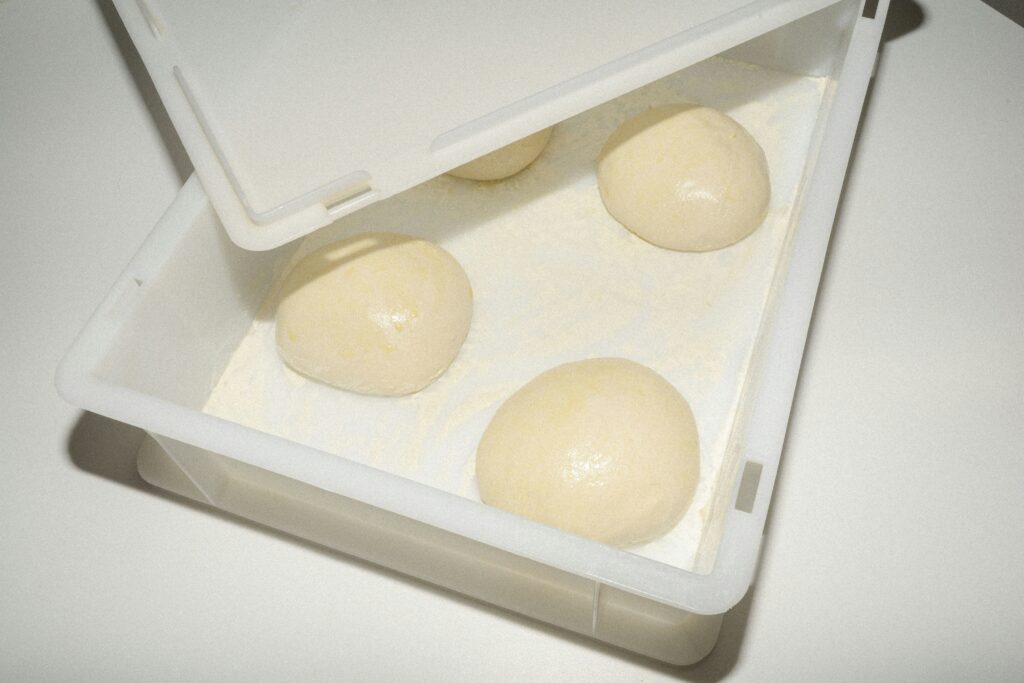

Today, in addition to refrigeration (keeping food at a temperature between 0°C and +10°C), freezing is increasingly used to preserve food and dough. It consists in bringing food to a temperature that can vary between -7°C and -18°C, according to the type of food, therefore keeping it at a temperature between -10°C and -30°C. Unfortunately, this method if on one hand extends the life of food products as well as that of pizza dough; on the other hand it does not completely stop the activity of enzymes, which therefore slowly degrade the product with time. Moreover, with this kind of preservation, during the defrosting phase, part of the nutritional and organoleptic values of food are lost, as well as the “rheological” values of pizza dough. In fact, frozen “DIY” pizza dough balls cannot reach a comparable result to the one obtained with fresh pizza dough, which is more elastic and extensible and, above all, leavens and cooks better. What usually negatively affects the quality of frozen products is not the low preservation temperature but the speed of freezing, which is the time needed for the food core to reach the maintenance temperature.

In fact, it differs from freezing because thanks to the use of a device called blast chiller, or rapid freezer, negative maintenance temperatures are reached in a very short time. The blast chiller cooling power is indeed such that only micro-crystals of water develop inside the products to be cooled. They do not cause damages neither to the biological structure nor to the organoleptic and nutritional characteristics of foods which are able, in this way, to keep almost unaltered also structure and taste.

It is precisely for this reason that, if made respecting all the appropriate technologies and using only top quality raw materials, quick-frozen pizza dough is capable of guaranteeing results comparable to excellent refrigerated pizza dough.

Quick-freezing can also guarantee excellent results in terms of healthiness of cooked foods and pizza toppings. In fact, with quick-freezing, the temperatures between 8°C and 68°C (the temperature interval within which bacterial proliferation finds its ideal conditions) are kept for a very short time.

If it is made with rapid freezers, quick-freezing is able to give a better chewability to the crust and a more “soft” consistency to the product consumed after defrosting and final baking. This is because during cooling the cold and dry air (at negative temperatures humidity is equal to 0) which is projected on the surface of the pizza creates small fractures on its crust and makes the inner part less moist.

If you want to start thinking about making quick-frozen dough, bread or pizzas, it is fundamental to consider that there is a specific legislation regulating the quick-frozen food sector. It is the Legislative Decree n. 110 of 27 Jan. 1992 – Implementing Directive 89/108/EEC concerning quick-frozen foodstuffs for human consumption, which defines and regulates everything that must be known and respected in this kind of production.