How to reduce space and organize pizzeria and work hours, customizing your business

Vacuum-packing can be essential in pizzeria even though those who do not know it are very suspicious about this technique of food preservation, which seems to impoverish and degrade the quality of raw materials. But are we really sure about this?

Vacuum-packing is not new, but in pizzeria it is usually considered as a way to wrap the goods and carry them from the supplier to the place. Still little known, it is crucial for those who use it, in terms of preservation of food and its properties.

Mainly to preserve a food product, to extend its life, to optimize the food-cost – this is useful to the owner in purely economic terms – and to preserve the quality. This is a return with greater added value because it benefits the customer, who eats our dishes in absolute safety and verifies their quality, but also the restaurant owner in terms of the restaurant image. If you add also the possibility to cook the food directly from the bag that contains it and the presence of indications of opening, expiry date and preservation on the label – compulsory by law and for the protection of consumers – the deed is done!

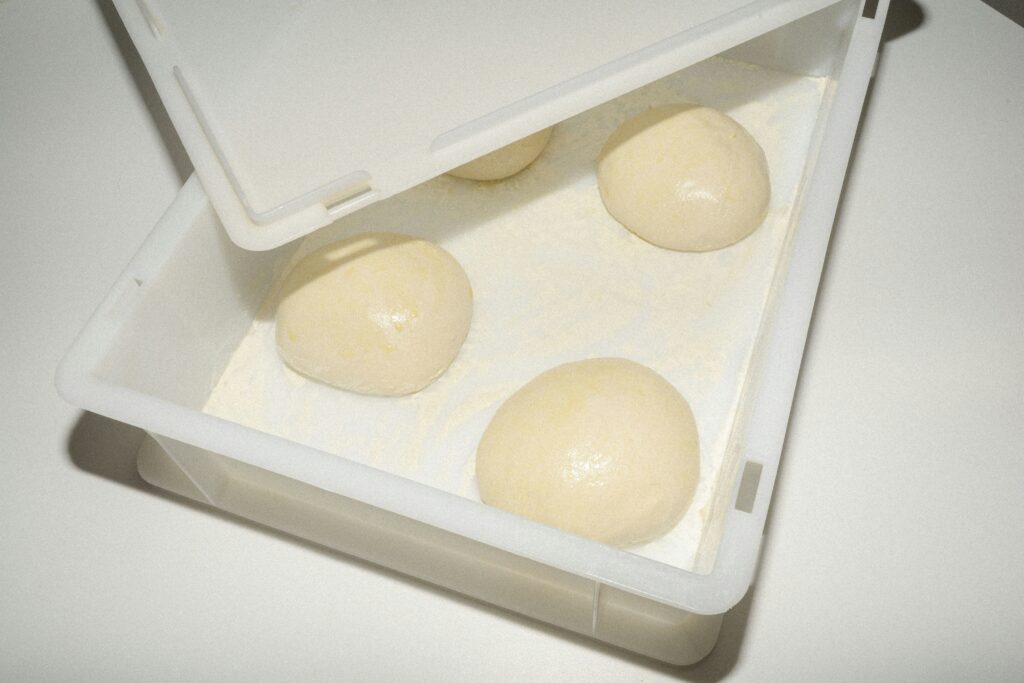

Putting a food product under vacuum means extracting the air – and with it the oxygen – from the bag by means of a pump and then sealing the bag. The best vacuum-packing machines are able to reduce the air inside the bag by 99.9%. The end result will be a film adhering perfectly to the food product. Extracting only part of the air simply means sealing the bag, without having the preservation effect that is normally obtained with a correct operation. If we remove the air from a container and then “seal” it, we obtain a vacuum packaging. Containers can be envelopes (bags), special rigid containers, thermoformed trays.

Removing air creates a hostile environment that prevents the activity of aerobic microorganisms, which need air to live and multiply. The microorganisms “fall asleep” and do not start those processes of deterioration of food, altering its organoleptic characteristics (external appearance, color, aroma, taste, texture), and its nutritional and chemical characteristics (digestibility, protein content, vitamins, starches). Moreover, together with the air, the polluting elements of biological, entomological and chemical nature present in the air itself and on the surface of the product are eliminated. Other benefits are due to the drying effect. In fact, the vacuum-packed product has less humidity because, at low pressures, the water contained in the food evaporates and is sucked towards the outside. The dry environment prevents the development of bacterial flora and avoids the deterioration of the product.

On the contrary, it sometimes happens that instead of extracting the air from the packages, a different type of gaseous substances is introduced, so that the products are presented in inflated packages.

In this case we talk about Preservation in protective atmosphere or Modified Atmosphere Packaging (MAP), a preservation technique that consists in substituting air with an inert gas, usually carbon dioxide, with nitrogen and oxygen. The advantages of protective atmosphere packaging are:

- Elimination of package crushing due to external pressure;

- Better bacteriostatic characteristics of the package, and therefore increased shelf-life;

- Maintaining the coloration, for example of red meat.

Furthermore, the carbon dioxide usually contained in technical gas mixtures dissolves in water and fat, thus lowering the pH of the product (more acidic environment/microclimate). A low pH allows for better food preservation because it inhibits bacterial activities and mold formation, creating an environment that is hostile to them. Doing so, you can avoid other physical and chemical preservation processes that are costly and can be invasive!

Be careful though, if the product is contaminated, vacuum or ATM packaging cannot correct the alteration processes that have already begun. The product must have a good quality, must be fresh and prepared with hygienic methods, in compliance with the HACCP methodology. Once opened, a Vacuum or MAP package must be consumed and cannot be reused. But the biggest question remains. How do I choose the best technique for the type of product I intend to preserve?

Beyond what has been said so far, some assumptions can be made. Whole salami arrives at the pizzeria under vacuum; but if it is sliced, is it preferable to use MAP preservation? Why remove salami from one bag and then put it in another?

How many times a week do you cut a sausage in a pizzeria? Every two days? With this system, by organizing the work, it can be done with longer intervals of time. The same goes for cheeses, some meats, sliced products, tomatoes and different kinds of vegetables.

In this way we could have always fresh and better preserved products for pizza topping, reduce waste and therefore have a food-cost estimate that does not include what is thrown away because badly preserved. Finally, having a more accurate stock planning greatly reduces the risk of running out of product and having to make last minute changes to the menu, with consequent inconvenience for customers and service.

With vacuum packing, the organization of pizzeria changes. In fact, it goes from having a vacuum-packed product purchased that requires attention and work to bags with products being already available for pizza topping.